This Workshop Manual has been compiled to assist Lotus Dealers throughout the world in the efficient repair and maintenance of the Lotus Europa models.

The various units and systems of the vehicle are dealt with in sections which are listed above are distinguished by a reference letter, this letter being the same as is used in other service publications (i.e., Section A is the chassis in both the Workshop Manual and the Parts Lists). Each section thus referred to opens with a contents page so that any particular operation can be easily located. Selecting the link above will open the proper section in your browser.

Service Information

Design changes, product improvements or changes in procedure subsequent to the publishing of this manual are given in Service/Parts Bulletins, which are issued regularly to all authorised Lotus Dealers. Should existing instructions be affected or additional information be needed, new pages to this manual will be issued to Lotus Dealers when convenient.

To ensure the manual is kept up-to-date, write the Bulletin number, the section and page number it affects and the subject matter in the space provided on page 8.

This electronic copy is not guaranteed to be up to date.

Technical Data

Comprehensive information regarding dimensions, tolerances, weights and torque loading figures of all nuts and bolts are given on page commencing 9.

Recommended Lubrication and Maintenance

Your attention is invited to Section 'O' of this manual for the Factory approved recommended lubricants and intervals of Periodical Maintenance.

Frost Precautions

Your attention is directed to the recommendations given in Section 'K' (Cooling System) of this manual on the importance of taking proper precautions against damage by frost.

Paint and Body Protection

When work is carried out on any part of the car where damage could be caused to the paint and body, i.e. working on the engine, or removing the windscreen, it is recommended that body protection covers be used.

Section Check List

***Section deleted due to non-applicability to electronic version***

SERVICE BULLETIN RECORD

To ensure that the information contained in the manual is up-to-date, Lotus Dealers are asked, when they receive them, to record in the columns below, the bulletin numbers with their subjects and the section and page number affected.

If reference is then made to these columns before turning to the appropriate section, it will be seen immediately if any amendment subsequent to the publishing of the manual is applicable.

***Table deleted due to non-applicability to electronic version***

VEHICLE IDENTIFICATION (Chassis Numbering)

Commencing at the 1st of January 1970, a new format has been used for Vehicle Identification.

An example of a new chassis number is given below, together with the full identification breakdown.

7001.010001P Both chassis and body numbers being the same

7001. Denotes year and month of manufacture (1970, January)

01 Denotes the production batch

0001 Denotes the chassis number

P Denotes the model

As there are at present 16 different model types, the following codes will

be used for model identification.

Model Style Market Suffix ----- ----- ------ ------ Elan STD Coupe G. Britain & N. Ireland A Elan STD Coupe Export B Elan STD Convertible G. Britain & N. Ireland C Elan STD Convertible Export D Elan S/E Coupe G. Britain & N. Ireland E Elan S/E Coupe Export F Elan S/E Convertible G. Britain & N. Ireland G Elan S/E Convertible Export H Elan Federal Coupe Export J Elan Federal Convertible Export K Elan +2'S' Coupe G. Britain & N. Ireland L Elan +2'S' Coupe Export M Elan +2'S' Federal Coupe Export N Europa Coupe G. Britain & N. Ireland P Europa Coupe Export Q Europa Federal Coupe Export R TECHNICAL DATA

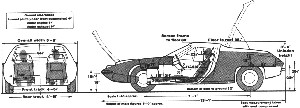

DIMENSIONS - Section Menu

Wheelbase 91 in. (231 1 cm.)

Track (at wheel hub) - Front 53 in. (134.6 cm.)

- Rear 53 in. (134.6 cm.)

Overall - Length 157 ¼in. (399.4 cm.)

- Width 64½ in. (163.8 cm.)

- Height 42½ in. (107.9 cm.)

Ground clearance 6 ½ in. (16.5 cm.)

Turning circle 44 ft. (13.4 m.)

Unladen weight - Series I 1350 lbs. (612 kg.)

- Series II 1566 lbs. (710 kg.)

CAPACITIES Engine sump (including filter) 7½ pints (4 litres; 9 U.S. pints) Transmission 3 pints (1.75 litres; 3.6 U.S. pints) Coolant (with heater) 18 pints (10.3 litres: 21.6 U.S. pints) Fuel 6 gallons (27 litres; 7.2 U.S. gallons) ENGINE - Section Menu General Number of cylinders 4 Capacity - Non Exhaust Emission 89.7 cu. in. (1470 cc.) - Exhaust Emission 95.5 cu. in. (1565 cc.) Stroke - Non Exhaust Emission 3.189 in. (81 mm.) - Exhaust Emission 3.307 in. (84 mm.) Bore - Non Exhaust Emission 2.992 in. (76 mm.) - Exhaust Emission 3.032 in. (77 mm.) Compression ratio (all) 10.25:1 Performance Max. BHP @ r.p.m. - Non Emission 82 @ 6,000 - Emission 80 @ 6,000 Max. Torque 79 lbs.ft. (10.92 kg.m.) @ 4,000 Road speed/1K RPM in top 17.7 m.p.h. (28.5 k.p.h.) Cylinder Head

Material Aluminium

Valve timing - Inlet opens 35° B.T.D.C.

- Inlet closes 65° A.B.D.C.

- Exhaust opens 65° B.B.D.C.

- Exhaust closes 35° A.T.D.C.

Valve seats/face angle 45°

Head diameter - Inlet 1.476 in. (37.5 mm.)

- Exhaust 1.220 in. (31 mm.)

Stem diameter - Inlet .315 in. (8 mm.)

- Exhaust .315 in. (8 mm.)

Guide Clearance - Inlet .0010/.0018 in. (.025/.045 mm.)

- Exhaust .0016/.0024 in. (.040/.060 mm.)

Rocker Clearance (cold)

- Inlet .008 in. (.20 mm.)

- Exhaust .010 in. (.25 mm.)

Valve springs - Type Helical, double

-Free length - Inner 1.492 in. (37.89 mm.)

- Outer 1.929 in. (49 mm.)

Valve guides

-Length - Inlet 1.968 in. (50 mm.)

- Exhaust 1.968 in. (50 mm.)

- Height above head .472 in. (12 mm.)

Camshaft Bearing #/Type 4/white metal Journal diameter 1.653 in. (42 mm.) Bearing running clearance .001/.0029 in. (.025/.075 mm.) End float .002/.0047 in. (.05/. 12 mm.) Tappets - Standard .473 in. (12 mm.) - Oversize .480 in. (12.2 mm.) Drive - Type Chain - Number of pitches 72 - Length (of pitch) .375 in. (9.525 mm.) - Width (of pitch) .225 in. (5.72 mm.) Crankshaft Diameter - Main journals 2.158 in. (54.8 mm.) - Crankpin 1.890 in. (48 mm.) End float - Dimension .002/.009 in. (.05/.23 mm.) - Controlled by Thrust washers on centre main bearing Bearings - Number 5 - Type Aluminium lead, thin wall - Running clearance .0015/.0031 in. (.038/.079 mm.) Maximum undersize for regrind .02 in, (.50 mm.) Connecting Rod Type 'H' section Material Steel forging Distance between centres 5.363 in. (13.62 cm.) Bearings - Type Aluminium Lead, thin wall - Running clearance .0007/.0028 in. (.017/.058 mm.) [1] - Side clearance .012/.022 in. (.310/.572 mm.) Gudgeon (Piston) Pin Location Force fit in connecting rod Diameter .787 in. (20 ram.) Class of fit - In piston .0001/.0003 in. (.003/.009 mm.) - In connecting rod .0007/.0015 in. (.020/.041 mm.) Piston Type Solid skirt Material Aluminium No. of rings - Compression 2 - Oil control 1 Piston clearance in cylinder liner Matched piston and liner sets Piston rings

Gap in liner (fitted)

- Compression .009/.015 in. (.25/.40mm.)

- Oil control .009/.015 in. (.25/.40 mm.)

Groove clearance

- Compression .0019/.0029 in. (.05/.075 mm.)

- Oil control .0005/.0023 in. (.015/.06 mm.)

Width

- Compression .078 in. (2 mm.)

- Oil control .157 in. (4 mm.)

Lubrication System

Pump

- Type Eccentric rotor

- Drive Skewgear from camshaft

Normal pressure (hot)

-2,000 r.p.m. 30 lbs.in.sq. (2. kg.cm.sq.)

Filter Full - flow ('throw away' canister)

For inner/outer rotor clearance, See Workshop Section 'E' (Engine)

FUEL SYSTEM - Section MenuPump operation Mechanical Air cleaner type Paper element (dry) Choke control Manual Carburetor - Non Exhaust Emission: Type Solex 35 DIDSA 2 (twin choke) Slow running speed 900-1,000 r.p.m. Primary Secondary Choke 26 26 Main jet 145 140 Air correction jet 135 150 Accelerator pump jet 40 Nil Power jet Nil 80/270 Inner venturi 28 32 Carburetor - Exhaust Emission: Type Solex 26 - 32 DIDSA 5 (twin choke) Slow running speed 1,000 +/- 50 r.p.m. Primary Secondary Choke 23.5 27 Main jet 120 142.5 Air correction jet 125 125 Slow running jet 60 95IGNITION SYSTEM - Section Menu Type Coil and distributor Firing order 1,3,4,2 No. 1 cylinder Nearest to clutch Ignition advance control Centrifugal Ignition timing (static) Non Exhaust Emission 4° B.T.D.C. Exhaust Emission T.D.C. Coil Ducellier 2765 A Sparking plugs - Type* Marchal 34 HS - Gap .023 in. (.584 mm.) (Alternates: Champion N4, Champion N7Y or Autolite AG22 may be used w/same gap) Distributor Type Ducellier 4 cylinder Drive Skew gear from camshaft Direction of rotation (from above) Anti-clockwise Contact breaker gap .016/.019 in. (.40/.50 mm.) Cam dwell angle 61° +- 3° Firing angles 0°, 90°, 180°, 270° +- 1° Centrifugal advance

(Non Exhaust Emission): Distributor Distributor

r.p.m. degrees B.T.D.C.

Below 550 No advance

920 7.8

1,000 8.0

2,000 13.0

3,000 18.0

Vacuum advance (Non Exhaust Emission): Distributor Vacuum degrees B.T.D.C. Hg. inches 1.5 3.937 4.6 7.874 6.5 11.811 7.0 15.748COOLING SYSTEM - Section Menu Type Centrifugal pump and fan Radiator cap relief valve 7 lbs .in .sq. (.49 kg.cm .sq .) Thermostat nominal temperature 68° C. Water pump belt tension 09375/.15625 in. (2.3812./3.9687 mm.) Alternator belt tenslon .28125/.375 in. (7.1437/9.525 mm.) (both at longest run)CLUTCH - Section Menu Make and type Ferodo 200 D, diaphragm spring Operation Cable Driven plate diameter 7.875 in. (20 cm.) Clutch assembly adjustment See Workshop Manual Section 'Q' (Clutch) Free movement at withdrawal lever .078/.125 in. (2/3 mm.)TRANSMISSION - Section Menu Type 4 forward speeds, all synchromesh and reverse Bearings - Mainshaft Taper rollers - Secondary gear cluster Taper rollers Bearings adiustment See Workshop Manual Section 'F' (Transmission) [Dial-up] Gear ratios - Top 1.03:1 - 3rd. 1.48:1 - 2nd. 2.25:1 - 1st. 3.61:1 - Reverse 3.08:1 Final drive: Type Hypold gear Bearings - Pinion Taper rollers - Diff./crown wheel: Taper rollers Bearings adjustment Pinion bearing pre-load See Workshop Manual Section 'F' (Transmission) [Dial-up] Crown wheel/pinion backlash .005/.010 in. (.127/.254 mm.) Number of teeth - Crown wheel 32 - Pinion 9 Final drive ratio 3.56:1 Speedometer gears: Driving Gear Driven Gear 46 F 6049, 6 teeth 46 F 6108, 12 teeth Pink Blue Overall ratios - Top 3.666:1 - 3rd. 5.268:1 - 2nd. 8.010:1 - 1st. 12.851:1 - Reverse 10.964:1FRONT SUSPENSION - Section Menu Type Independent Springs - Number of coils 17 - Wire diameter .348 in. (8.83 mm.) - Length - Free 12.75 in. (32.38 cm.) - Fitted 7.75 in. (19.68 cm.) - Rate 100 lbs.in. (1.15 kg.m.) Front hub end float .002/.004 in. (.05/.10 mm.)STEERING - Section Menu Type Rack and pinion Steering angles - Camber 0° to +- 30' - Castor 3° +- 30' - Swivel(kpi) 9° +- 30' Toe - in 3/16 in. (4.76 mm.) to 1/16 in. (1.6 mm.) Condition for checking toe - in 6t in. (16.5 cm.) ground clearance at bottom of chassis closing plate.REAR SUSPENSION - Section Menu Type Independent Spring - Number of coils 19½ - Wire diameter .329 in. (8.35 mm.) - Length - Free 16.2 in. (41.15 cm.) - Fitted 10.4 in. (26.42 cm.) - Rate 72 lbs.in. (.83 kg.m.) Wheel camber 0° to 2° Negative Toe - in Zero to 3/16 in. (4.76 mmm.)BRAKES - Section Menu Make and type Girling hydraulic (servo optional) Front brakes - Disc diameter 9.75 in. (24.76 cm.) - Pads material Ferodo DS.31 Total disc run out .004 in. (.10 mm.) Rear brakes - Drum dia. and width 8 in. (20.3 cm.) x 1.25 in. (3.175 cm.) [3] - Lining material Don. 242 Handbrake type Mechanical, on rear onlyWHEELS AND TYRES - Section Menu

Wheel

- Type Pressed steel bolt on

- Size 4½J

Tyres*

- Type Firestone F.100 tubeless or,

Dunlop SP Sport with tubes.

Tyres*

- Size 155-80 x 13

*If inner tubes are fitted, it is essential that these are of the

correct type for radial ply tyres.

Tyres

- Pressure (cold): At speeds BELOW At sustained speeds

100 mph (160 kph) ABOVE 100 mph (160 kph)

- Front 18 lbs.in.sq. 24 lbs.in.sq.

(1.27 kg.cm.sq .) (1.69 kg.cm.sq.)

- Rear 28 lbs.in.sq. 34 lbs.in.sq

(1.97 kg.cm.sq.) (2.39 kg,cm.sq.)

ELECTRICAL EQUIPMENT - Section MenuBattery Type Exide 6 VTA 29 L Capacity @ 20 hr. rating 39 amp.hr. Voltage and polarity 12 volt negative earth Fuses Quantity and rating 2, 35 amp. Alternator Type SEV/Motorola A. 1230 Nominal system voltage 12 Charging voltage 13.2 Maximum output (hot) 30 amps. @ 3,000 r.p.m. Control box type SEV/Motorola E.144 Field coil resistance 5.2 +- .2 ohms. @ 25 C. measured across slip rings Starter Type Paris-Rhone D.8 E 49 Drive Pre - engaged Lock torque 8 lbs.ft. (1.1 kg.m.) @ 355 amps. Lamp Bulbs (all 12 volt) Headlamp - RHD, LHD 410 (45/40W) with 989 (6W) pilot - France 411 (45/40W) with 989 (6W) pilot - North America Sealed beam unit Front and rear indicators 382 (21W) Indicator repeater 501 (5W capless) Stop and tall lamps 380 (21/6W) Rear number plate lamp 254 (6W festoon) Reverse lamp - Up to 46/0541 382 (21W) - From 46/0542 273 (21W festoon) Interior lamp 254 (6W festoon) Panel (instrument) lamps 987 (2.4W) Warning lamps 987 (2.4W)ADDITIONAL INFORMATION - Section Menu Distributor Centrifugal Advance (Exhaust Emission): Distributor Distributor r.p.m, degrees B.T.D.C. Below 550 No advance 800 2.5 1,000 10.5 1,250 11.5 1,500 13.0 1,750 14.5 2,000 15.5 2,250 16.5 2,400 17.0 Maximum advance Distributor Vacuum Advance (Exhaust Emission): Distributor Vacuum degrees B .T.D.C. Hg. milllmetres 1.3 100 3.3 150 4.5 200 5.6 250 6.5 300 7.0 350 Maximum advanceTORQUE LOADING FIGURES - Section Menu ENGINE lbs .ft. kg.m. Cylinder head - tighten cold 54 - 60 7.46 - 8.29 (See also Section ' E') Rocker arm pillar 15 - 20 2.07 - 2.76 Crankshaft - Main bearing caps 45 6.22 - Cone 30 4.14 - Sprocket 45 6.22 Flywheel 40 5.53 Oil pump - To cylinder block 9 - 12 1.25 - 1.65 - Strainer flange 16 - 20 2.25 - 2.75 Manifold to cylinder head 10 - 20 1.38 - 2.76 CLUTCH Clutch assembly to flywheel 25 3.45 TRANSMISSION Gearbox casing (halves) - 7 mm. bolts 15 2.07 - 8 mm. bolts 20 2.75 Differential case to crown wheel - 10 mm. bolts 45 6.22 - 11mm. bolts 65-80 8.98-11.06 Differential bearing adjusting nuts 15 2.07 Pinion bearing nut 85 11.75 Speedometer drive worm 75-85 10.36-11.75 Reverse selector pivot 20 2.75 Side cover plates 15 2.07 FRONT SUSPENSION AND STEERING

Stub axle retaining nut 65 - 75 8.98 - 10.36

Ball joint

- To vertical link 38 - 42 5.25 - 5.80

- To upper wishbone 12 - 15 1.65 - 2.07

Lower wishbone

- To trunnion* 35 4.83

- To damper* 50 - 60 6.91 - 8.29

Inner wishbone retaining nut* 50 - 60 6.91 - 8.29

Caliper mounting plate to hub 22 - 27 3.04 - 3.73

Steering arm to vertical link 22 - 27 3.04 - 3.73

Steering tie-rod ball joint 26 - 28 3.59 - 3.87

Steering tie-rod adaptor 50 6.91

Steering column impact clamp 26 - 32 3.59 - 4.42

* Tighten with suspension in static condition

REAR SUSPENSION lbs.ft. kg.m. Lower link pivot bracket 18 -23 2.48 - 3.18 HUBS

Brake disc to hub 22 - 27 3.04 - 3.73

Front hub spindle nut * 5 - 6 .69 - .83

Rear hub retaining nut ** 150 20.7

*Tighten nuts to this torque loading while rotating hub to ensure

bedding of taper rollers. Slacken nut one 'flat', then insert split pin.

**Assemble with Loctite 'AV'. A rotational free play NOT EXCEEDING

.005 in. (.127 mm.) between hub and shaft measured at the wheel stud

should be used for LEFT - HAND hubs.

BRAKE HYDRAULIC SYSTEM CONNECTIONS 3/8 in. UNF female (bundy and hose connections) 8 - 10 1.10 - 1.38 3/8 in. UNF male (bundy to master cylinder,etc.) 5 - 7 .69 -.96 7/16 in. UNF male 7 - 10.5 .96 - 1.45 3/8 in. bore servo bundy (5/8 in.UNF male) 14 - 21 1.93 - 2.90 Stop lamp switch 12 - 15 1.65 - 2.07 Brake hose to banjo 12 - 15 1.65 - 2.07 7/16in. UNF female (bundy to reservoir) 12 - 14 1.65 - 1.93 Torque Wrenches Torque wrenches in daily use should be checked at intervals, not exceeding 3 months, to ensure that accuracy is maintained. GENERAL - NUTS AND BOLTS 1/4 in. UNF and UNC 5 - 7 .69 - .96 5/16 in. UNF and UNC 12 - 15 1.65 - 2.07 3/8 in. UNC 17 - 22 2.35 - 3.04 3/8 in. UNF 22 - 27 3.04 - 3.73 7/16 in. UNC 30 - 35 4.14 - 4.85 7/16 in. UNF 40 - 45 5.53 - 6.22 1/2 in. UNC 45 - 50 6.22 - 6.91 1/2 in. UNF 50 - 60 6.91 - 8.29 9/16 in. UNC 60 - 70 8.29 - 9.68 9/16 in, UNF 65 - 75 8.98 - 10.36 5/8 in. UNC 75 - 85 10.36 -11.75 5/8 in. UNF 100 - 110 13.82 - 15.20 |

Editors Notes:

-

[1] Corrected .0228 to .0028. [JJ]

[2] Not in original manual. Added for clarification. [JJ]

[3] Changed from "1.5 in. (3.8 cm.)" to correct original manual error. ( [JJ]

Other Notes: [edit]

This area is a public scratchpad for notes.

Please be courteous with what you post, and do not erase someone else's work.