Q.l – REMOVING, OVERHAULING AND REFITTING THE CLUTCH - Section Menu

A/ REMOVING

-

Remove the gearbox (see Section F).

Mark the position of the clutch mechanism with reference to the flywheel.

Remove the clutch mechanism securing bolts.

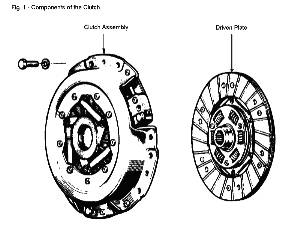

Remove the clutch mechanism and the friction disc.

B/ CHECKING

-

Check all the parts,

Replace any defective parts.

Refacing the clutch friction face on the flywheel is not possible.

The flywheel is to be replaced if this face is damaged (see Section E).

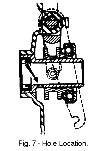

Check to ensure that there is an 8 mm (.315") diameter hole at the bottom of the withdrawal pad guide.

If there is not, drill one as shown on page 5.

C/ REFITTING

-

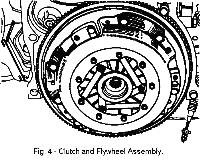

Degrease the flywheel friction face.

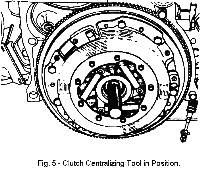

Fit the disc with the offset on the hub towards the gearbox (transmission case).

Position the clutch mechanism by means of the position mark made during dismantling, when applicable.

Centralize the disc by means of mandrel (Part No 46Q 6006).

Slowly screw in the bolts, which secure the mechanism and then finally tighten them.

Refit the gearbox (transmission case).

Q.2 - REPLACING THE CLUTCH SHAFT BEARING - Section Menu

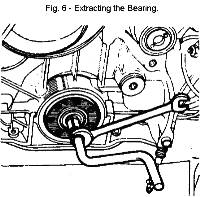

Remove the gearbox (see Section F).

Remove:

- the clutch mechanism and friction disc.

- the flywheel.

Extract the bearing by means of extractor (Part No 46E 6351).

Fit the new bearing with the seal facing towards the outside.

NOTE - The bearing is supplied pre-greased and is therefore not to be cleaned.

Refit:

- the flywheel (see Section E).

- the clutch friction disc and mechanism.

- the gearbox (see Section F).

Q.3 - REPLACING THE SEAL ON THE CLUTCH SHAFT - Section Menu

Remove the gearbox (see Section F).

Separate the clutch housing from the gearbox (transmission case).

Remove the seal.

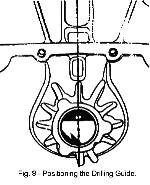

Check to see whether there is a hole, 8 mm (.315") in diameter at the bottom of the withdrawal pad guide.

If there is no hole, drill one as follows:

Place tool (Part No 46Q 6009).

Place the thrust washer in position and screw up the retaining nut.

Position the centre of the hole in the tool on the vertical centre line of the clutch housing and tighten the nut.

Move the clutch withdrawal pad as far as it will go forward and hold it in position by means of a spacer.

Slowly drill the hole with a 7 mm (.276") diameter drill.

Remove the tool and carefully remove the burrs from the edges of the hole.

Fit the new seal with its lip towards the gearbox (transmission case).

Fit the clutch housing to the gearbox paying attention not to damage the lip on the seal as it passes over the splines.

To do this, wrap adhesive plastic tape round the splines.

Refit the gearbox (see Section F).

Q.4 - ADJUSTING THE CLUTCH CLEARANCE - Section Menu

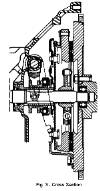

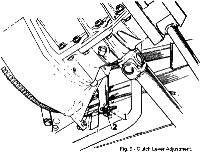

Loosen lock nut (1).

Screw nut (2) in or out to obtain a clearance of: 2 to 3 mm (5/64 to 1/8") at the end of the lever.

Tighten the lock-nut.

Q.5 - REPIACING THE CLUTCH WITHDRAWAL PAD - Section Menu

Remove the gearbox (transmission case) (see Section F).

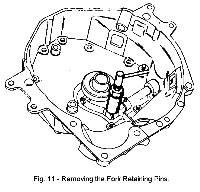

Remove the fork retaining pins by means of:

- tool (Part No 46Q 6007) for cylindrical pins A.

- tool (Part No 46Q 6008) for splined pins B.

Swing the withdrawal fork and remove the withdrawal pad.

Grease the withdrawal pad guide by means of DUCKHAMS 'KE.24' (or equivalent).

Fit the new withdrawal pad.

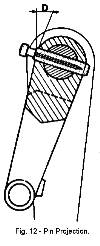

Align the holes in the withdrawal fork with that in its shaft.

Fit the pins: leave the correct projection D with reference to the withdrawal fork D " 1 mm (1/32").

NOTE: Only fit splined pins B under repair.

Refit the gearbox (transmission case) (see Section F).

Q.6 – REMOVING AND REFITTING THE CLUTCH CABLE - Section Menu

A/ REMOVING

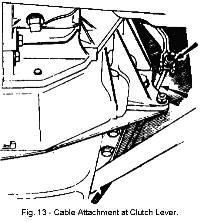

Disconnect the cable at the clutch withdrawal lever.

Push out the cable end fitting from its clamp.

Pull the outer cable forwards to remove it from the engine mounting bracket.

Remove the split pin from the clevis situated on the right hand lever of the pedal shaft.

Remove the clevis pin.

Free the clevis pin and cable assembly from its lever on the pedal shaft.

Pull the edge of the carpet away from the tunnel side at the front of the drivers seat to reveal the outer cable bracket on the chassis side.

Pull the outer cable slightly rearwards to release it from the bracket and disengage the inner cable from the slot on the bracket.

Pull the cable forward to remove it from the vehicle.

B/ REFITTING

-

Carry out the removal operation in reverse.

Check that the inner cable is greased and slides freely within the outer cable before fitting to the vehicle.

Adjust the clutch clearance.

Q.7 – REMOVING AND REFITTING THE CLUTCH PEDAL - Section Menu

A/ REMOVING

-

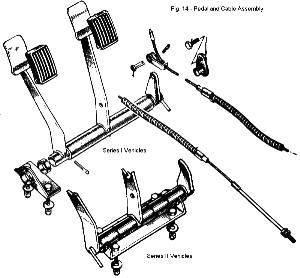

The clutch and brake pedals are constructed as an assembly using a common shaft.

Consequently, should it be necessary to remove either pedal, the assembly must be detached.

-

Disconnect the cable at the clutch withdrawal lever.

Remove the split pin from the clevis situated in the right hand lever of the shaft.

Remove the clevis pin.

Free the clevis and cable from its lever on the pedal shaft.

Remove the split pin from the clevis on the brake pedal.

Remove the clevis pin and disconnect the clevis from the brake pedal, taking care not to pull the pushrod out of its socket on the master cylinder.

-

Remove the two Nyloc nuts and penny washers that secure the studs of the outer pedal mounting bracket to the under-surface of the body.

Remove the bracket and pull the pedal assembly from the spigot mounting on the tunnel.

Series II vehicles:

-

Remove the four Nyloc nuts and penny washers from the studs of the pedal mounting bracket that protrude beneath the under-surface of the vehicle.

Remove the bracket from the vehicle.

B/ REFITTING

-

Carry out the removal operation in reverse.

Check that the clutch shaft is greased and pivots freely within the brake tube.

Replace the bearing in the mounting bracket if necessary.

Before connecting the brake and clutch see that the pedals pivot freely.

Adjust the clutch clearance, and check the brakes for correct operation.

ADDITIONAL INFORMATION

Q.8 - CLUTCH CABLE FORWARD ABUTMENT - Section Menu

- Disconnect the clutch cable from the pedal (Section 'Q.6'). Pull back the carpet from the driver's side of the transmission tunnel adjacent to the seat to expose the forward abutment.

- Pull the outer cable slightly rearwards to release from abutment.

- Drill out the 'pop' rivets which secure the abutment to the tunnel.

- Using a new abutment {Part No. A46 A 0170), cut off the bent part (which is slotted to take the cable) and discard. Drill out the holes in both the original and modified abutments, and in the tunnel side to take No. 10 UNF setscrews.

- Refit the original abutment and with a second operator below the car, secure the new strengthening piece and original with two setscrews (Part No. 026 B 6001) and nuts (Part No. YUFN 030F), fixing the nuts from beneath the car.

- Replace clutch cable and carpet.

The method of mounting the forward clutch cable abutment has been revised to provide a stronger fixing. This has been introduced as a running change and no chassis numbers are available.

If the occasion arises where it is necessary to incorporate the stronger fixing, the following procedure is recommended.

Other Notes: [edit]

This area is a public scratchpad for notes.

Please be courteous with what you post, and do not erase someone else's work.