G.1 - GENERAL DESCRIPTION - Section Menu

'Bolt on' wheels of pressed steel construction are fitted to the Europa.

The spare wheel is located in the front luggage compartment and is retained by a clamp and bolt.

Radial ply tyres (with inner tubes where applicable) of Firestone, Goodyear or Dunlop manufacture have been fitted as original equipment depending on their availability.

Tyres pressures should be maintained at the pressures given in 'Technical Data' and should be checked every 1,000 miles (1,600 km.).

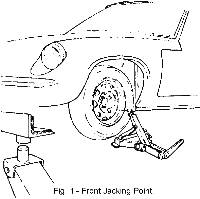

The front hubs are mounted on two taper roller bearings and are designed to run with a specified end float (see 'Technical Data').

Overtightening will destroy the bearings.

The rear hub bearings consist of ball races pressed into the bearing housing and located by circlips.

G.2 - FRONT HUBS - Section Menu

To Adjust:

-

Remove the hubcaps (naive plates).

Loosen the road wheel securing nuts.

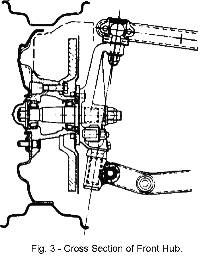

Apply the handbrake and raise the front of the car on a suitable jack (see Fig. l).

Place chassis stands in position then remove jack.

Remove the wheel securing nuts and take off wheel.

Extract the split pin locking the hub securing nut and discard.

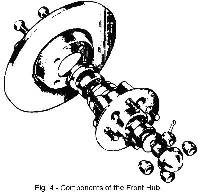

Mount a dial gauge in such a position that its plunger is against the front face of the hub (see Fig.2).

Tighten the securing nut sufficiently to give an indicated end float (see 'Technical Data').

Back off the nut one flat (60º) then insert a new split pin to lock.

Re-pack the hub with grease (see section O) working the grease well past the large washer below the securing nut.

ONLY HALF FILL THE HUB to allow for expansion.

Replace the wheel and refit the wheel nuts.

Repeat above procedure for opposite wheel.

Lower vehicle to the ground and tighten the wheel nuts.

Replace the hubcaps.

G.3 - FRONT HUBS - Section Menu

To remove

-

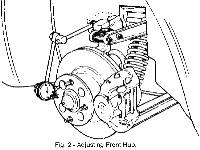

Remove the road wheel (section G.2).

Break the fluid supply to the front caliper at its connection.

Fit plug to pipe to avoid ingress of dirt.

Detach the brake caliper (see section 'J').

Remove the split pin locking the securing nut and discard.

Remove nut and washer.

From the rear of the brake disc, remove the bolts, which retain both disc and hub.

Pull off hub.

To replace

-

Clean the mating faces of the hub and disc.

These must be scrupulously clean if disc run out is to be avoided.

Replace the bearings as necessary.

Fit the hub and disc assembly, tightening the securing bolts to the torque loading given in 'Technical Data'.

Secure the hub with its nut and split pin, repacking with grease and adjusting end-float (Section G.2).

Refit the caliper. Remove plug from pipe end and refit pipe to caliper.

Tighten pipe nut to the torque loading given in 'Technical Data'.

Bleed the brakes (see section 'J').

Replace the road wheels and lower car to ground after removing chassis stands.

Tighten the road wheel securing nuts.

G.4 - REAR HUBS - Section Menu

No adjustment is provided on the rear hub bearings, maintenance therefore being limited to fitting new bearings.

To remove

-

Remove the hub caps.

Loosen the road wheel securing nuts.

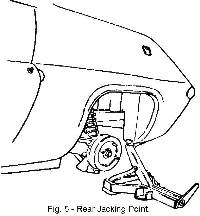

Raise the rear of the car (see Fig.5) and support with chassis stands then remove jack.

Remove the wheel securing nuts and take off wheel.

Remove the hub securing nut with its washer.

Check that the handbrake is fully released and pull off the drum.

Using a suitable extractor pull off the hub.

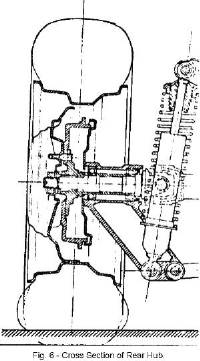

To remove the bearings, which are situated within the bearing housing of the radius arm, (see Fig.6) it is necessary to remove the radius arm itself (see section 'D').

To replace.

-

Replacing the bearings is a reversal of the removal procedure outlined in section 'D'.

It is suggested that whilst the bearings are of the sealed type, it is advisable to grease the internal surfaces of the bearing housing to help prevent corrosion.

Locate the outboard drive shaft.

Lining-up the splines, push on the rear hub and secure with its nut and washer.

Tighten the nut to the torque loading given in 'Technical Data'.

Replace the road wheel and lower car to ground after removing chassis stands.

Tolerances

-

S.M.M.T. (Society of Motor Manufacturers and Traders) standard tolerances of the wheel only are:

-

Wobble

-

The lateral variation measured on the vertical inside face of a flange must NOT EXCEED 0.05in. (1.27 mm.).

-

The difference between the high and low points of a rotating wheel measured at any location on either bead seat must NOT EXCEED 0.05in. (1.27 mm.).

Wheel alignment

-

Settings for front and rear wheel alignment are given in 'Technical Data'.

Excessive misalignment caused by kerb impact or other accidental damage will result in severe tyre wear and faulty steering.

Steel wheels maintenance

-

Ensure that the bead seats and flange faces are kept free from rust and dirt.

Locally damaged flanges may be corrected by careful hammering but a buckled wheel, i.e., one which no longer conforms to the tolerances quoted, must be replaced.

Wheel removal

-

Slacken the four securing nuts of the desired wheel using the special wheel brace or spanner supplied with the car

Raise the vehicle and fully release the wheel nuts.

Pull off wheel.

When replacing the wheel, ensure that it is fully seated on the hub by carefully cleaning the mating surfaces of the wheel and hub BEFORE replacing the nuts.

Do NOT grease or oil the threads on either the hub or the wheel nuts, just CLEAN.

Wheel nuts

-

Check security of wheel nuts at between 5 and 10 miles (8 and 16 km.) after initial fitting, and thereafter every 1,000 miles (1,600 km.).

- Inflation pressure.

- Wheel balance.

- Steering swivels for wear.

- Wheel hub bearing condition and adjustment.

- Wheel alignment.

Tyre care

-

Check at intervals of every 1,000 miles (1,600 km.) that the tyre pressures are correct.

Ensure that the tyres are cold when checking the pressures.

Never bleed air out of a warm tyre in order to achieve the recommended pressure, since when the tyre cools it will be under-inflated.

If oil or grease have been in contact with a tyre wipe the affected area with a cloth lightly moistened with petrol or trichloroethylene.

New tyres

-

When new tyres are required it is essential to fit the same type as those remaining on the vehicle.

The characteristics of tyres vary considerably therefore, if tyres are changed for those of a different type, then it is imperative that all tyres including the spare, are changed at the same time.

If trouble is experienced with replacement tyres, reference should be made to the manufacturers concerned.

Effect of temperature

-

Air expands with heating and tyre pressures increase as the tyres warm up.

Pressures increase more in hot weather than in cold weather and as a result of high speed.

Pressure in warm tyres should not be reduced to standard pressure for cold tyres.

'Bleeding' the tyres increases their deflections and causes their temperatures to climb still higher.

The tyres will also be under-inflated when they have cooled.

The rate of tread wear may be twice as fast at 50 m.p.h. (80 k.p.h.) as at 30 m.p.h. (48 k.p.h.).

High speed causes increased temperatures due to more deflections per minute and a faster rate of deflection and recovery.

The resistance of the tread to abrasion increases with increased tyre temperature.

Inflation pressures

-

Severe and persistent under-inflation produces unmistakable evidence on the tread.

It also causes structural failure due to excessive friction and temperature within the casing.

Pressures higher than those recommended reduce tread life by concentrating the load on a small tread area.

Excessive pressures overstrain the casing, cause rapid wear and make the tyres more susceptible to impact fractures and cuts.

Camber, Castor and King Pin Inclination (see also section 'C').

-

These angles normally require no attention unless they have been disturbed by a severe impact or abnormal wear of front end bearings.

It is always advisable to check them if steering irregularities develop.

Wheel camber, usually combined with road camber, causes a wheel to try to turn in the direction of lean, due to one side of the tread attempting to make more revolutions per mile than the other side.

The resulting increased tread shuffle on the road and the off-centre tyre loading tend to cause rapid and one-sided wear.

Unequal cambers introduce unbalanced forces, which try to steer the car one way or the other.

This must be countered by steering in the opposite direction which increases tread wear.

Castor and king pin inclination by themselves have no direct bearing on tyre wear but their measurement is often useful for providing a general indication of the condition of the front end geometry and suspension.

Braking

-

Irregular braking torque produces excessive local tread wear generally caused by eccentric brake discs or the use of incorrect pad lining materials.

'Spotty' wear may be due to a variety of faults, and if present, the following items should be checked:

Wheel alignment and Road camber

-

Fins and feathers on the tread surface are due to severe wheel misalignment.

The condition takes the form of a sharp 'fin' on the edge of each pattern rib and the position of this indicates the direction of misalignment.

Excessive toe-in will cause fins on the inboard edges of the pattern rib.

Excessive toe-out will cause fins on the outboard edges of the pattern rib.

NOTE: Finning on nearside front tyre ONLY may be due to severe road camber conditions and cannot be eliminated by mechanical adjustment.

In this event frequently change the position of the affected wheel.

Tyre and Wheel Balance

-

The original degree of balance is not necessarily maintained, and it may be affected by uneven tread wear, by repairs, by tyre removal and refitting or by wheel damage and eccentricity.

The vehicle may also become more sensitive to unbalance due to normal wear of moving parts.

If roughness or steering troubles develop and mechanical investigation fails to disclose a possible cause, wheel and tyre balance should be suspected.

Static unbalance can be measured when the tyre and wheel assembly is stationary.

Dynamic unbalance can be detected only when the assembly is revolving.

There may be no heavy spot, that is, there may be no natural tendency for the assembly to rotate about its centre due to gravity, but the weight may be unevenly distributed each side of the tyre centre line.

Laterally eccentric wheels give the same effect.

During rotation the offset weight distribution sets up a rotating couple, which tends to steer the wheel to left and right alternately.

Dynamic unbalance of tyre and wheel assemblies should be measured on a Balancing Machine and suitable corrections made when the vehicle shows sensitivity to this form of unbalance.

Where it is clear that a damaged wheel is the primary cause of severe unbalance it is advisable to renew the wheel.

It is recommended that the complete assembly of wheels and tyres are balanced at intervals of every 3,000 miles (5,000 km.).

Balance Weights

-

When balancing alloy wheels it is IMPORTANT to use only the specified type of weight.

These are of the 'stick-on' type.

DO NOT use the 'knock-on' type (for steel wheels) with alloy wheels.

ADDITIONAL INFORMATION

G.7 - REAR HUBS - Section Menu

Commencing at Chassis No. 0218, selective assembly has been adopted in Production to ensure a good fit between hub and shaft.

It should be noted that the L/H hub is most susceptible to loosening, therefore a rotational free play NOT EXCEEDING 0.005 in. (0.127 mm) measured at the wheel stud, should be maintained between hub and shaft.

Smear faces of tab washer with Loctite 'AV' and tighten the hub nut to the torque loading given in 'Technical Data'.

G.8 - REAR HUB BEARING SEAL - Section Menu

A seal (Part No. 064 D 0171) is available which will assist in extending the life of the inner bearing.

When fitted to cars already in service, which were not previously fitted with the seals, the inner bearing housing corner MUST be chamfered 45° to a depth of 0.330 in. (0.762 mm), this greatly assisting fitting.

The seal should be fitted so that it abuts the inner bearing and its lip smeared with a medium grease containing 10% graphite.

Other Notes: [edit]

This area is a public scratchpad for notes.

Please be courteous with what you post, and do not erase someone else's work.