C.1 - REMOVING AND REFITTING A FRONT SUSPENSION UNIT - Section Menu General notes:

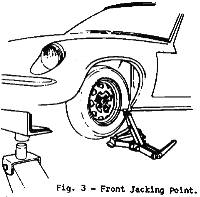

An Individual suspension unit can be removed by simply raising the required side of the vehicle with the jack supplied in the tool kit, using the correct jack location for the front.

Should it be necessary to remove both suspension units, it is suggested that normal workshop jacking equipment be utilised, interposing a block of wood between the front suspension cross member and the crutch of the Jack.

It will be found that extensive use is made of nylon insert locking nuts on the suspension parts. It is suggested that replacement nuts be obtained, together with any other parts required, thus obviating the possibility of old nuts being inadvertently used in assembly.

THE LOCKING EFFECTIVENESS OF NYLON INSERT NUTS DETERIORATES WITH RE-USE.

Removing a front suspension unit:

Before raising the front of the vehicle, check that the handbrake is firmly applied, or chock the rear wheels front and back.

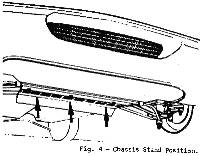

Remove the front hub cap and loosen the front road wheel securing nuts. Place the Jack under the centre of the chassis front cross member, taking care to avoid damaging the fibreglass areas to the front and rear of the member. Support the vehicle by placing trestles or stands under the front cross member immediately behind the steering unit access panel, in the position indicated in Fig. 4.

Remove the road wheel securing nuts, and lift off the road wheel. Replace the securing nuts on their studs to avoid their loss and consequential damage to the stud threads. Disconnect the front brake hose from the caliper by undoing the nut to the rear of the bracket holding the brake pipe to the vertical link, or remove the two bolts holding the caliper and the brake pipe to the caliper mounting bracket. Tie the unit conveniently out of the way taking care not to damage or kink the pipes. Undo the locknut and pull the brake hose forward through the bracket, clear of the suspension unit, and drain the brake fluid into a clean jar.

Remove the Nyloc nut on the end of the steering arm, and separate the track rod end from the steering arm using a suitable taper puller.

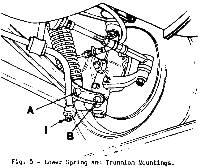

Undo the locknuts (I Fig.5) securing both ends of the anti-roll bar to their respective studs situated on the lower mounting of each spring/damper unit. Swing the roll-bar slightly downwards off the mounting and remove the cup washers and rubber bushes.

Loosen the Nyloc nuts to the front and rear of the lower wishbone at its mounting pivot pins on the chassis.

Loosen the Nyloc nut of the spring/damper bolt ('A' Fig 5) at the lower wishbone mounting, three or four turns.

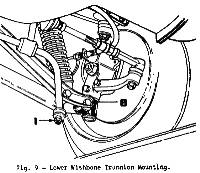

Undo the Nyloc nut and remove the bolt ('B' Fig 5) attaching the lower wishbone to the trunnion allowing the wishbone to splay slightly and swing down wards under the action of the spring/damper unit to take up its fully extended condition.

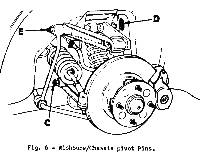

Remove the nuts and washers from the front and rear lower wishbone chassis mounting pivot pins (Fig 6) and pull off each individual arm (making up the wishbone) from the chassis pivots.

Remove the grommet 'D' from the bodywork to the rear of the upper wishbone mounting pivot pin.

Pull the carpet away from the box in the foot well, exposing the hole.

Undo the Nyloc nuts and remove the washer on either end of the upper wishbone pivot pin ('E' Fig 6).

With a suitable drift, drive the pin rearwards, towards the exposed hole releasing the suspension components in the process. Care must be exercised not to damage the threads during this operation.

Remove the suspension unit to the bench for dismantling.

Refitting a front suspension unit:

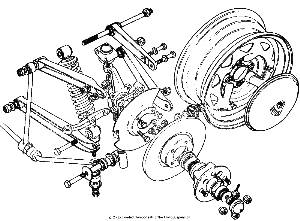

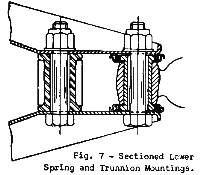

Before refitting check for correct assembly of the components, that all worn or damaged components are replaced, and that new seals and nuts are used in assembly (Fig 7).

The trunnion should be fitted to the vertical link in the manner prescribed in the ensuing chapter and should be in its first working position. This will allow the trunnion to turn at least 60° to either side of the straight ahead position without binding.

To refit the suspension unit, reverse the procedure outlined previously. [1]

Assembly is simplified if the top wishbone of the unit is secured to the chassis initially. During this operation the unit should be supported, and care taken to ensure that it does not swing about its pivots with consequential damage.

Do not tighten the bolt at the lower spring/damper mounting. This bolt also serves to clamp the lower wishbone halves together.

The lower wishbone assembly must therefore be carefully raised into position on either side of the trunnion with the seals and washers interposed and the holes aligned before the trunnion bolt is inserted.

Leave the nuts on the wishbone pivot pins, damper bolt and trunnion bolt slack until the vehicle is in the static laden condition, then tighten to the recommended torque loadings outlined in the technical specifications section of this manual.

When connecting up the roll bar, do not forget the attachment on the opposite suspension unit.

Assemble cup washers and bushes in the correct order when attaching the anti-roll bar to its mounting points on the lower spring/damper eyes.

If the brake caliper has been removed inspect the flexible pipe and its attachment points for wear and damage, replacing if necessary.

Connect up the pipe taking care not to kink the pipe.

Replenish the system with brake fluid and bleed the system.

Refit the road wheel, remove the stands or lower the vehicle to the ground.

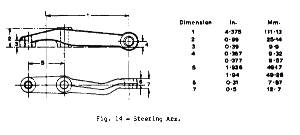

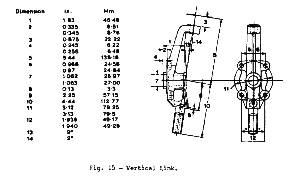

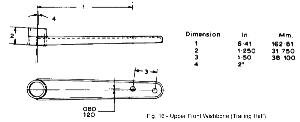

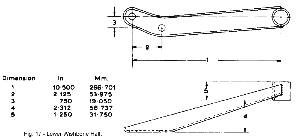

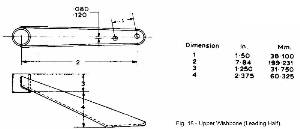

Tighten the wheel nuts and refit the wheel trim and nave plate. C.2 - REMOVING AND REPLACING COMPONENTS OF THE FRONT SUSPENSION - Section Menu Top ball joint To remove: To replace: Bottom Trunnion To remove: To refit: Spring/Damper Unit To remove: To replace: Vertical link To remove: To refit: Stub Axle To remove: To refit: Bottom Wishbone To remove: To refit: Upper Wishbone To remove: To refit: Anti Roll - Bar To remove: To refit: C.3 - CHECKING AND OVERHAULING THE COMPONENTS - Section Menu The spring/damper units To Dismantle Testing the Damper Unit Checking the spring Damper settings Front Upper Wishbones Assessment of accidental damage The following dimensioned illustrations assist in the assessment of accidental damage.

It is suggested that any components which have sustained damage or are suspect in any way, should first be removed from the vehicle as instructed, then cleaned and accurately measured on a surface table.

The measurements obtained should then be compared with those given in the appropriate illustration and a decision made relative to the serviceability of the components.

C.4 - STEERING AND SUSPENSION GEOMETRY. - Section Menu The term 'steering geometry' refers to the lay out of the steering mechanism and any of its dimensions, linear or angular, which contribute to the required behavior of the steering system. The steering system is always designed to comply with the specification of the front suspension, in order that the best possible steering behavior is obtained under all conditions.

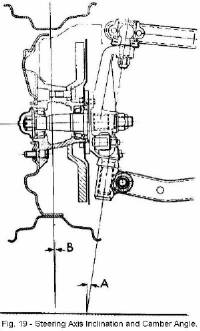

For example, Toe-in and Camber are classed as suspension geometry; Steering axis inclination (K.P.I) and Castor ate classed as steering geometry.

Under normal service conditions, the only item requiring attention is the front wheel alignment. The necessity for a full geometry check is required following rectification or repair damage to the front suspension or steering, or if excessive tyre wear is evident, or steering difficulties ate experienced. The only angles which are adjustable, are those for wheel alignment, the castor, camber and steering axis inclination being set in production and are non-adjustable.

When checking suspension (front or rear) and steering geometry, the following requirements must be met: Tools and Appliances There are many different types of tools and appliances available for checking front suspension and steering geometry, but only a reputable brand should be used.

Whatever the equipment used, the manufacturer's instructions must be carefully observed and the vehicle must be loaded with the weights shown.

The equipment for checking front suspension and steering geometry shown here is obtainable from Dunlop Co. Ltd.

The equipment required for geometry checks is as follows: Front Wheel Alignment The front wheels are considered to toe-in when the setting of the front wheels is such that the distance between the front of the wheels is less than that at the rear of the wheels, when measured in the same plane. The correct 'toe-in' is given in Technical Data. Front Wheel Camber Angle This is the angle of inclination of the road wheel from the vertical when viewed from the front (see Fig. 19). If the road wheel is set vertically, the camber will be zero.

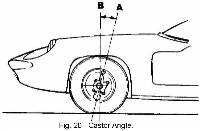

This angle is non-adjustable, but should be checked in the event of accident damage or if steering difficulties are experienced (see Technical Data). Castor Angle Viewed from the side of the vehicle, this is the angle at which the pivoting axis of the front suspension assembly is inclined from the vertical (see Fig. 20).

Inclination rearwards is termed positive castor, and inclination forwards is termed negative castor. If the pivoting axis is vertical, the castor will be zero.

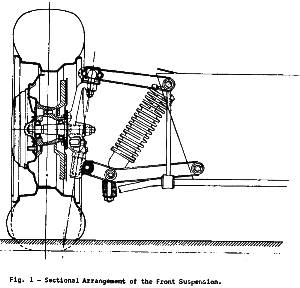

This angle is non-adjustable, but should be checked in the event of accident damage or if directional instability is experlenced (see Technical Data). Steering Axis Inclination (K.P.I.) Viewed from the front of the vehicle, this is the angle at which the pivoting axis of the front suspension assembly is inclined inwards from the vertical (see Fig. 1). This angle is non-adjustable, but should be checked in the event of accident or if steering difficulties are experienced (see Technical Data). Editors Notes: Other Notes: [edit]

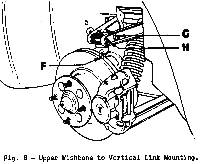

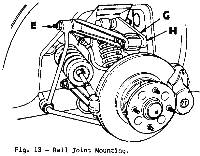

Remove the Nyloc nut and washer ('F' Fig 8) at the top ball joint attachment to the vertical link.

Use a ball joint separator to remove the ball joint from the vertical link.

Remove the two bolts ('G and H' Fig 8) that clamp the upper wishbone halves to the ball joint housing.

NOTE: When the top ball joint is removed, the hub assembly is free to tip outwards and must be steadied to prevent damage.

Ensure that the contacting faces of the ball joint and vertical link are perfectly clean.

Loosely attach the ball joint to the top wishbone arms by the two clamping bolts.

Fit the ball joint to the vertical link and fully tighten it using a plain nut and washer.

Replace the plain nut by a Nyloc nut.

Fully tighten the two bolts that secure the joint between the wishbone.

Remove the hub (see section G).

Remove the four bolts and spring washers, the dust shield and the caliper bracket from the vertical link.

Slacken the bolt ('A' Fig 5) attaching the damper/spring unit to the lower wishbone three or four turns.

Remove the trunnion bolt and swing the vertical link about its upper ball-joint away from the bottom wishbone.

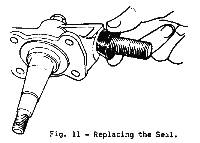

Unscrew the trunnion from the vertical link and remove the rubber seal.

Remove the bush assembly from the trunnion.

Examine all dismantled items and renew those which are unserviceable.

Reverse the procedure outlined above.

Refit the bush assembly to the trunnion liberally smearing the bushes with grease.

Fit a new rubber seat to the vertical link. Screw the trunnion on to the vertical link as far as possible and then unscrew it to its first working position.

This will allow the trunnion to turn at least 60° to either side of the straight ahead position without binding.

NOTE:

The right hand vertical link has a right hand thread and the left hand vertical link has a left hand thread and the base of the right hand trunnion has a reduced diameter.

Take care to see that the seals and washers are correctly fitted on either side of the trunnion (see Fig 7).

Ease the trunnion back within the confines of the lower wishbone halves by carefully raising or lowering the lower wishbone to align the hole for the trunnion bolt.

Replace the trunnion bolt: leaving the Nyloc nut slack.

With the vehicle in the static laden condition, finally tighten all nuts to the torque loadings outlined in the technical specifications section.

Undo the locknut ('I' Fig 9) securing both ends of the anti-roll bar to their respective studs, situated on the lower mounting eye of each spring/damper unit. Swing the roll bar slightly downwards off the, mountings and remove the cup washers and rubber bushes.

Place a suitable support under the suspension unit to relieve the load and steady it during the ensuing operations.

Slacken the bolt at the lower wishbone - damper mounting.

Slacken the bolt at the lower wishbone - trunnion mounting.

Slacken the nuts on the lower wishbone - chassis mounting.

Remove the grommet from the bodywork to the rear of the upper wishbone mounting pivot pin.

Pull the carpet away from the box in the foot well, exposing the hole.

Undo the Nyloc nuts and remove the washers on either end of the upper wishbone mounting pivot pin.

With a suitable drift, drive the pin rearwards towards the exposed hole through the upper eye of the anti roll bar link, and the leading half of the upper wishbone.

Care must be exercised during this operation not to damage the threads.

Remove the bolt at the lower wishbone-damper unit mounting, and lift out the spring/damper unit.

Check the dampers.

(The servicing of a spring/damper unit is not generally practicable and the damper should be renewed if any defects are apparent (see section C.3).

To facilitate assembly it is suggested that the upper spring/damper and front upper wishbone half mountings be located in their correct position by the pivot pin initially. This will enable the more accessible lower spring/damper mounting to be eased into position between the lower wishbones and the bolt passed through them to retain it.

Remove the hub (see section G).

Remove the four bolts and spring washers) the dust shield and the caliper bracket from the vertical link. Pull the steering arm forwards from its location in the vertical link.

Slacken the bolt attaching the spring/damper unit to the lower wishbone three or four turns.

Undo the Nyloc nuts and washers and remove the two bolts securing the ball joint housing to the upper wishbone halves.

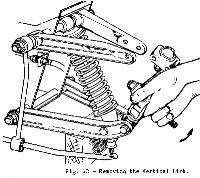

Remove the vertical link from the trunnion and remove the component to the bench for further dismantling (see Fig 10).

Remove the seal at the base of the link.

Remove the Nyloc nut and washer at the ball joint attachment on the vertical link. Use a ball-joint separator to remove the ball joint from the vertical link.

Undo the hexagonal plug at the base of the vertical link and check that the lubrication channel is clear.

Reverse the procedure outlined above.

Note: When refitting the bush assembly to the vertical link, liberally smear the bushes with grease.

Fit a new rubber seal to the vertical link.

Screw the trunnion onto the vertical link as far as possible and then unscrew it to its first working position.

This will allow the trunnion to turn at least 60° to either side of the straight ahead position without binding.

NOTE:The right hand vertical link has a right hand thread, and the left hand vertical link has a left hand thread and the base of the right hand trunnion has a reduced diameter for identification purposes.

Lubricate the link (see section O) and replace the hexagonal plug.

Remove the vertical link as described previously.

Remove the Nyloc nut and washer on the inner end of the stub axle.

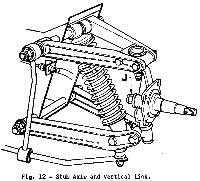

Press out the stub axle ('J' Fig 12); this is a taper fit within the vertical link.

Reverse the procedure outlined above, and continue as for Vertical Link.

Remove the Nyloc nuts and washers to the front and rear of the lower wishbone-chassis pivot pin.

Remove the Nyloc nut and washer and withdraw the trunnion bolt.

Remove the Nyloc nut and washer and carefully withdraw the bolt attaching the spring/damper unit to the lower wishbone.

Pull the lower wishbone halves from either side of the chassis pivot pin.

Reverse the above procedure.

Renew all Nyloc nuts and replace all worn or damaged parts where required.

Place wishbone halves on either side of the chassis pivot pin leaving them slack for the time being.

Insert the bolt through the lower wishbone halves and the lower spring damper mounting, leaving the Nyloc nut slack.

To remove the wishbone bushes, use a suitable pilot drift, the outer periphery of which must bear on the outer sleeve of the bush. Press out the bush.

Replace with hew bushes as necessary.

Ensure that the Seals and washers are correctly fitted on either side of the trunnion.

Ease the trunnion back within the confines of the lower wishbone halves by carefully raising or lowering the lower wishbone to align the holes for the trunnion bolt.

Replace the trunnion bolt leaving the Nyloc nut slack.

Finally, with the vehicle in the static laden condition tighten all the nuts to the torque loadings specified in the technical specifications section.

Slacken the bolt securing the spring/damper unit to the lower wishbone.

Slacken the bolt securing the trunnion to the lower wishbone.

Slacken the nuts on either end of the lower wishbone pivot pin at the chassis mounting.

Remove the nuts ('I' Fig 9) holding the roll-bar to the lower point on the spring damper unit on both suspension units.

Remove the two bolts 'G & H' (Fig 13) on the upper wishbone ball-joint mounting allowing the vertical link and hub assembly to be released from the upper wishbone.

Note: The hub assembly is free to tip outwards and care must be exercised to prevent the unit from tipping outwards or pivoting and damaging the track-rod joint.

Remove the grommet from the bodywork to the rear of the upper wishbone mounting pivot pin.

Pull the carpet away from the box in the foot well, exposing the hole.

Undo the Nyloc nuts and remove the washers from either end of the upper wishbone mounting pivot pin.

With a suitable drift, drive the pin rearwards towards the exposed hole, to release the anti-roll bar top link location and suspension parts in the process.

NOTE: Care must be exercised to avoid damaging the threads of the pivot pin.

Replace bushes as per lower wishbones (see page 11) if necessary.

Reverse the procedure outlined above, replacing all worn or damaged items in the process. Leave all nuts slack until vehicle is in static laden condition and then tighten to the recommended torque figures outlined in the technical specifications section of this manual.

NOTE: If replacing wishbones on vehicles pre unit No 46/0480, see special note page 13.

Undo the locknuts securing both ends of the anti-roll bar to their respective studs situated on the lower mounting eye of each spring/damper unit.

Swing the roll bar slightly downwards off each mounting and remove the cup washers and rubber bushes.

Remove the Nyloc nuts and washers from the front of both pivot pins 'E' (Fig 13).

Pull the top eye of both roll bar links forward off the pivot pins and remove the anti-roll bar.

Reverse the procedure outlined above, replacing all worn or damaged items in the process.

Interpose the anti roll bar ends between each set of cup washers and rubber bushes before fitting the locknuts.

Using a clamp type spring compressor, slightly compress the road spring to relieve the load on the spring retainer collet, situated beneath the top mounting eye of the unit.

Slide the collet out from the assembly (it will be found to be slotted for this purpose).

Carefully release the load on the spring and remove the compressor.

Withdraw the damper unit from the spring.

The servicing of a spring damper is not generally practicable. The damper should be renewed if any of the following defects are apparent:

- damaged or dented body;

If none of these defects is apparent, Hold the unit vertically and perform the following manual operations:

- bent piston rod;

- loosened mounting;

- fluid leakage.

Slowly extend and compress the damper approximately 10 times, moving it to the limit of its stroke in both directions.

Comparative performance can be assessed against the action of new damper after taking care to expel air, but allowance must be made for greater resistance in the new unit due to the slightly increased friction between the piston rod and its oil seal.

There should be appreciable and constant resistance in both directions.

Reject damper units having the following defects:

- none or only slight resistance in one or both directions;

- excessive resistance; cannot be operated manually;

- pocket of no resistance when reversing direction.

The spring should be thoroughly cleaned and an initial check made for correct alignment. Any misalignment may show by rub marks on the inner sides of the spring coils where contact has been made with the shock absorber body.

A dimension check should be made over the free length of the spring and compared with that of a new component ie. 12.75 in.

Where spring balance facilities are available, the rating of the spring should be checked ie. 100 lb per in.

NOTE: Revised front springs part No A46C010 have been fitted to vehicles 46/0480 onwards. These must be used in conjunction with the items mentioned below.

Front dampers with revised settings (Part No A46C710, identified by a white paint mark) have been fitted in production from vehicles 46/0480 onwards. If replacement spring/damper units are to be fitted, new upper wishbones also associated with this modification must be used.

New upper wishbones fitted in production from unit No 46/0480 must be used in conjunction with the spring/dampers above, can be identified as follows:

46C 093 - L/H (Upper wishbone - leading) marked 'LH'

46C 094 - R/H (Upper wishbone - leading) marked 'RH' replaces 46C087

46C 095 - L/H (Upper wishbone - trailing) marked 'LH'

46C 096 - R/H (Upper wishbone - trailing) marked 'RH' replaces 46C088

L.H. seat 150 lbs (68 kg.)

These weights will give 6½ in. (16.5 cm.) ground clearance at bottom of chassis closing paste.

R.H. seat 150 lbs (68 kg.)

Fuel tank 50 lbs (22.7 Kg.)

Optical wheel alignment gauge (Dunlop 'AGO/30')

Camber, castor and steering axis inclination gauges (Dunlop 'OG/4-5')

Front wheel turntable gauges with wheel ramps to suit. The ramps are used to keep the car on a level plane, but will not be necessary if the turntable gauges are sunken flush with the floor (part of Dunlop ('CG/4-5' kit).

Inclination outwards at the top of the wheel is termed positive camber, and inclination inwards is termed negative camber.

NOTE: Whilst the checking of the camber, castor, and steering axis inclination angles are described separately, they are in fact a combined operation.

[1] Changed the phrase "previously in chapter b." to "previously." [JJ]

This area is a public scratchpad for notes.

Please be courteous with what you post, and do not erase someone else's work.