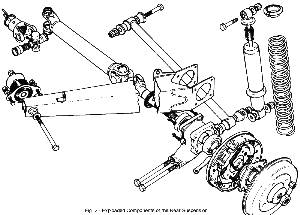

D1 - REMOVING AND REFITTING A REAR SUSPENSION UNIT - Section Menu General notes

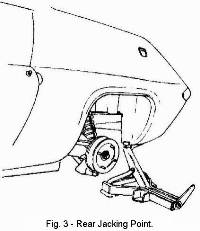

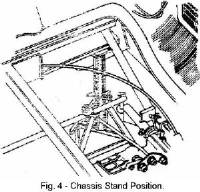

In order to remove an individual suspension unit, it is necessary to raise one side of the vehicle. This may be achieved by using the jack supplied in the tool kit, placed in the correct jack location for raising the rear of the car (Fig.3). Support the raised side by placing a stand or block under the chassis at the position indicated (Fig.4), and remove the jack.

Should it be necessary to remove both suspension units, it is suggested that normal workshop equipment be utilised. The crutch of any jack or lifting appliance should be placed centrally under the rear gearbox mounting cross member.

Support the rear of the vehicle on both sides by placing trestles under the chassis in the position indicated. Removal of both suspension units complete with drive shafts is facilitated if the cross member above the rear of the chassis is removed. Better access to the roll pins on the inner universal joints is gained. It will be found that extensive use is made of Nylon insert lock nuts on the rear suspension assembly.

It is suggested that replacement nuts be obtained at the same time as any other parts required, thus obviating the possibility of old nuts being inadvertently used in assembly.

Removing a unit Refitting a rear suspension unit.

D2 - REMOVING AND REFITTING THE COMPONENTS OF THE REAR SUSPENSION - Section Menu

Spring damper unit. To remove: To refit: Radius arm. It will be found generally praferrable to remove the suspension unit complete if the radius arm is damaged or distorted in any way. The procedure outlined in Section D3. should consequently be adopted for its removal. However, the radius arm can be removed from the vehicle as follows: To refit: Lower link. To remove: To refit: D3 - CHECKING AND OVERHAULING THE COMPONENTS - Section Menu The Spring/Damper Units. To dismantle: Testing the Damper Unit. If none of these defects is apparent, hold the unit vertically and perform the following manual operations: Checking the Spring. A dimension check should be made over the free length of the spring and compared with that of a new component i.e. 16.2 in.

Where spring balance facilities are available, the rating of the spring should be checkedfor the factory setting of 72 lb per in. Damper Settings. These dampers, part No: A46DO07, replace the original items 46D007 and should be fitted in pairs when replacement is required. Assessment of accidental damage. It is suggested that any components which have sustained damage or are suspect in any way, should first be removed from the vehicle as instructed, then cleaned and accurately measured on a surface table.

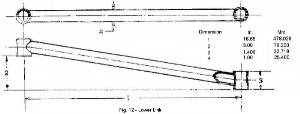

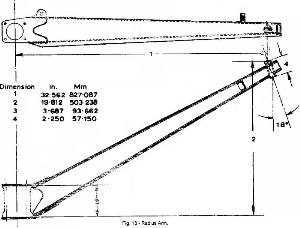

The measurements obtained should then be compared with those given in the appropriate illustration and a decision made relative to the serviceability of the components.

ADDITIONAL INFORMATION

D4 - LOWER LINK PIVOT BRACKET (on Gearbox) - Section Menu Commencing at Chassis No. 0389, the attachment of the bracket to the bottom of the transaxle uses the following hardware (replacing the original Renault bolts): D5 - REAR WHEEL TOE - IN - Section Menu Commencing at Chassis No. 2414, the rubber insulators located at the front end of the "Y" of the chassis have been relocated from the outside to the inside of the "Y". This modification has been made necessary to ensure that design toe-in (see Technical Data) is able to be set through the use of size 7 (AN7) [3] packing washers between the inside of the suspension radius arm and the insulator.

If difficulty is experienced in service on cars prior to that given above, the following procedure is recommended: Editors Notes: Other Notes: [edit]

Remove the rear luggage compartment by undoing the two belts set in the floor of the unit, taking care to note the quantity and position of the spacer washers interposed between the cross member and the under surface of the compartment.

Before raising the rear of the vehicle, check that the hand brake is firmly applied, and chock the front wheel to the front and rear.

Remove the rear hub cap and loosen the rear road wheel securing nuts.

Raise the vehicle by placing a jack under the centre of the lower rear cross member or at the position outlined in the preceding chapter.

Support the vehicle by placing trestles or stands beneath the chassis at the position indicated, allowing the suspension unit to assume its fully unsprung condition (Fig 4).

If the left hand suspension unit is to be removed the tail-pipe and silencer (muffler) assembly should be removed as follows:

Undo the nut attaching the silencer (muffler) strap to the clutch housing.

Undo the clip clamping the silencer to the front pipe and withdraw the component rearwards.

Remove the road wheel.

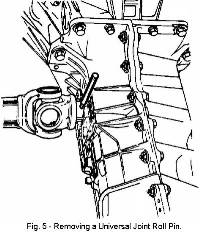

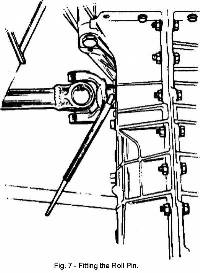

Drive the roll pin from the inner universal joint on the transmission shaft by means of a drift (Part No 46F 6171).

With the chassis cross member and exhaust system removed (if necessary) it is possible to stand within the confines of the engine compartment thus simplifying this operation. Care must be exercised that the drift be struck 'solidly and squarely' as any light tapping attempts may only succeed in burring the components.

Release the handbrake lever and pull off the brake drum.

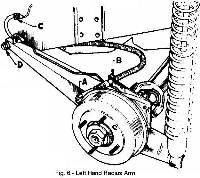

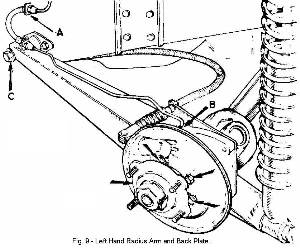

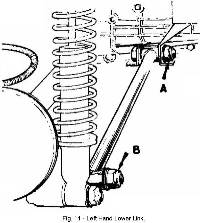

Remove the split pin and pull out the clevis pin ('A' Fig 6) to release the handbrake lever at the drum end.

Pull out the handbrake outer cable retaining clip ('B' Fig 6) and release outer cable from its mounting bracket on the radius arm.

Drain the hydraulic system (see brake section J).

Release the flexible pipe at the forward end of the radius arm by undoing the union ('C' Fig 6) at the bracket on the chassis.

Undo the Nyloc nut and remove the bolt and washer of the lower link attachment at the gearbox end.

Undo the Nyloc nut and remove the bolt and washers of the spring/damper unit at its top attachment to the chassis cross member. Undo the nut and remove it with the penny washer from the resilient mounting of the radius aim attachment on the inside of the chassis member.

Withdraw the mounting bolt 'D' from the outside of the radius arm releasing the arm from the chassis (Fig 6).

Free the drive shaft from the transmission shaft by withdrawing it outwards from its splines.

Remove the suspension assembly to the bench for further dismantling.

Before refitting,, check for correct assembly of the components, that all worn or damaged items are replaced and that new seals and Nyloc nuts are used in assembly.

To refit the suspension unit, reverse the procedure outlined previously. [2]

Assembly is simplified if the splined end of the drive shaft is coupled to the gearbox transmission shaft initially, and the unit supported on blocks whilst the other items are attached to the vehicle.

Lightly grease the splines on the gearbox transmission shaft.

Align one of the pin holes at the bottom of one of the splines in the drive shaft with a hole on top of one of the splines in the gearbox transmission shaft.

To make it easier to fit the transmission shaft roll pins (Fig 7) use the cranked end of the drift (Part No 46F 6171).

Leave the Nyloc nuts attaching the lower link, radius arm and suspension strut slack, until vehicle is in the static laden condition.

Before assembly it is advised to connect the flexible brake pipe to its attachment bracket on the forward end of the radius am, leaving the more accessible connection to the chassis until assembly is completed.

Take care not to damage or kink the pipes.

Replenish with brake fluid and bleed the system.

Check the handbrake for correct operation and adjust if necessary.

Check that the handbrake is firmly applied, chock the front wheels front and rear.

Remove the rear hub cap and loosen the rear road wheel securing nuts.

Raise the rear of the vehicle by placing a jack under the centre of the lower rear cross member or at the position outlined in section D1 by means of the jack supplied in the tool kit.

Allow the suspension unit to assume its fully extended condition.

Remove the road wheel.

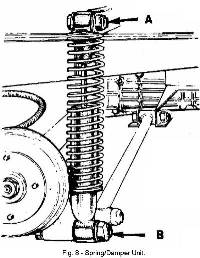

Undo the Nyloc nut and washer ('A' Fig 8) and remove the bolt holding the top of the spring damper unit to the rear chassis cross member.

Undo the Nyloc nut and washers ('B' Fig 8) holding the lower mounting eye of the spring/damper unit to the rear hub carrier.

Ease the top eye outwards from the forked end of the cross member.

Pull the spring/damper unit rearwards off the mounting, bolt and remove the unit to bench for inspection etc.

Reverse the procedure outlined above.

Before refitting, check the damper unit for correct operation (see Section D3.)

The servicing of a spring damper unit is not generally practicable and the damper should be renewed if any defect are apparent.

Fit new Nyloc nuts to top and bottom spring damper mounting bolts in assembly and leave slack until vehicle is in static laden condition.

Finally, tighten the two nuts to the recommended torque settings outlined in the technical Specification section.

Before raising the rear of the vehicle, check that the handbrake is firmly applied, and chock the front wheels to the front and rear.

Remove the hub cap.

Knock back the tab washer and slacken the hub nut. Loosen the rear road wheel securing nuts.

Raise the rear of the vehicle by placing a Jack under the centre of the lower rear cross member or at the position shown in Figure 3, [1], allowing the suspension to assume its fully unsprung condition.

Support the vehicle by placing stands or trestles beneath the chassis at the position indicated.

Remove the road wheel.

Release the handbrake lever and remove the brake drum.

Remove the split pin and pull out the clevis pin to release the handbrake lever at the drum end.

Remove the handbrake outer cable retaining clip, and release the outer cable from its mounting bracket on the radius arm.

Drain the hydraulic system (See Brake Section J)

Release the flexible pipe at the forward end of the radius arm by undoing the union ('A' Fig. 9) at the bracket on the chassis.

Undo the union ('B' Fig. 9) attaching the brake pipe to the slave cylinder on the rear of the back plate.

Undo the hub nut, remove the tab washer.

Remove the hub using a suitable hub extractor.

Remove the four bolts and lock washers holding the brake back plate to the rear hub carrier and pull the assembly off.

Undo the Nyloc nut and washer at the lower spring damper, unit attachment to the bearing housing.

Place a suitable support under the suspension unit and remove the bolt.

Undo the nut and remove it together with the penny washer from the resilient mounting of the radius arm on the inside of the chassis.

Withdraw the mounting bolt from the outside of the front radius arm.

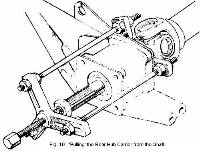

Replace the hub nut to protect the thread and the thread and the end of shaft from 'belling' in the next operation.

Using a suitable drawer, pull the rear hub carrier off the splined shaft (Fig.l0) complete with the radius arm.

Sufficient clearance can be obtained if the radius arm is allowed to swing down from the confines of the body.

Undo the four bolts and spring washers attaching the inside flange of the radius arm to the bearing housing and separate the components.

Before commencing assembly scrupulously clean and check the radius arm parts, paying particular attention to the rear hub carrier, bearings and seal.

Replace where necessary using Lotus Service Parts.

Revised rear hub carriers (Parts No: A46D004 (LH) and A46DO05 (RH) have been fitted in production from unit No 46/0051. These replace the components 46D004 and 46D005 respectively, and should be fitted when replacement is required.

NOTE: Early production vehicles can be updated at this juncture by fitting a seal 55.25 mm x 41.1 mm x 8.5 mm No 54D171 or modification released to protect the inner bearings (see Section G).

To assemble, reverse the procedure outlined previously.

Smear the lip of the seal with grease before assembling.

Secure the radius arm to the inner face of the rear hub carrier using new lock washers with the set bolts.

Fit new Nyloc nuts to the lower link and spring damper mounting bolts.

Fit a new Nyloc nut to the radius arm mounting bolt.

Leave nuts slack and tighten when vehicle is in static laden condition to the recommended torque settings outlined in the Technical Specifications section.

Check that the handbrake is firmly applied, chock the front wheels front and rear.

Remove the rear hub cap and loosen the rear road wheel securing nuts.

Raise the rear of the vehicle by placing a jack under the centre of the lower rear cross member or at the position outlined in section D.1. by means of the jack supplied in the tool kit.

Allow the suspension unit to assume its fully extended condition.

Remove the road wheel.

Undo the Nyloc nut and washer and remove the bolt ('A' Fig.11) holding the inner end of the lower link to its attachment bracket on the gearbox.

Ease the eye downwards from its location in the bracket. Undo the Nyloc nut ('B' Fig.11) and washer holding the outer end of the link to the mounting bolt on the rear hub carrier. Pull the link rearwards off the mounting bolt and remove the component for checking.

Reverse the procedure outlined above.

Before refitting, check the link for misalignment or damage and the bushes for wear. Renew if necessary.

Fit new Nyloc nuts to both inner and outer bolts on assembly, and leave slack until vehicle is in static laden condition.

Finally tighten the two nuts to the recommended torque settings outlined in the Technical Specification section.

Using a clamp type spring compressor, slightly compress the road spring to relieve the load on the spring retainer collet, situated beneath the top mounting eye of the unit.

Slide the collet out from the assembly (it will be found to be slotted for this purpose).

Carefully release the load on the spring and remove the compressor.

Withdraw the damper unit from the spring.

The servicing of a spring damper is not generally practicable. The damper should be renewed if any of the following defects are apparent:

- damaged or dented body;

- bent piston rod;

- loosened mounting;

- luid leakage.

Slowly extend and compress the damper approximately 10 times, moving it to the limit of its stroke in both directions.

There should be appreciable and constant resistance in both directions.

Reject damper units having the following defects:

- none or only slight resistance in one or both directions;

Comparative performance can be assessed against the action of a new damper after taking care to expel air, but allowance must be made for greater resistance in the new unit due to the slightly increased friction between the piston rod and its oil seal.

- excessive resistance; cannot be operated manually;

- pocket of no resistance when reversing direction.

The spring should be thoroughly cleaned and an initial check made for correct alignment. Any misalignment may show by rub marks on the inner sides of the spring coils where contact has been made with the shock absorber body.

Rear dampers with revised settings (identified by a white paint mark) have been fitted in production from the following vehicle number 46/0254.

The following dimensioned illustrations assist in the assessment of accidental damage.

5/16 in. x 1½ in. UNF, 'S' high tensile bolts

Tighten bolts to a torque loading of 18-23 lbs.ft. (2.48-3.18 kg.m.).

5/16 in. Internal diameter plain washer

5/16 in. UNF self-locking nuts

Remove the radius arm ('Section D.2').

Remove the insulators by releasing the 2 bolts on each securing them to the chassis "Y".

Replace the insulators on the inside face of the chassis with the plate located against the Y section and rubber insulator towards the center of the car, using a reinforcing plate (Part No. 054 A 0251) on the outside face of the chassis. Note that the bolts are assembled from the outside in the following sequence - bolt, plain washer, reinforcing plate, chassis, plain washer or spacer, insulator, large washer, nut.

[1] The word "shown" is substituted for "outlined" and the word "Figure" for "chapter". [SV]

[2] Changed the phrase "previously in chapter B." to "previously." [JJ]

[3] Changed "8" to "7", since the bolt is a XUFB0772, 7/16 (AN7), 72/16" long." [BB]

This area is a public scratchpad for notes.

Please be courteous with what you post, and do not erase someone else's work.