Removing the

doors of a Lotus Europa; the realities.

By Geoff Searle

Intro

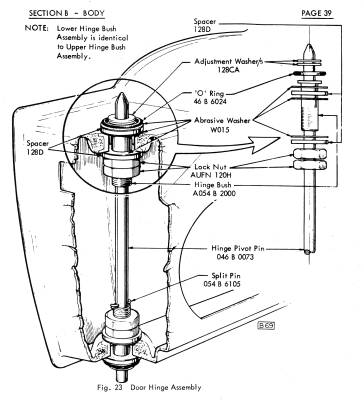

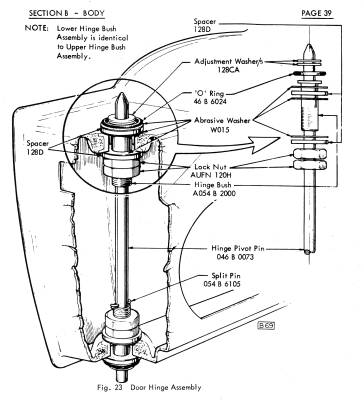

The hinge arrangements of

the Europa are famously naff or brilliant value engineering depending on who you

ask. Two square bobbins are bonded (inadequately) into the doors top &

bottom and a Ĺ inch pivot pin passes up through a bobbin in the top of the sill

into a hollow bolt (hinge bush), whose movement within the square bobbin allows

adjustment of the doorís ďhangĒ. Then up to a similar arrangement going into the

wing. The hinge rod is held in place by a split pin & on the Twin

Cam/Special is supposed to come out through a hole in the sill usually covered

by the trim piece. (fig1) Fig1

In reality adjustment is a

nightmare, durability poor & the hinge rod rusts solid into the hollow bolts

& wears away at the bobbins until the time comes for action.

The Classic method

(revised)

Remove the trim from the

door & the wires from the window motor (especially the bolted earth).

Liberally coat the hinge rod & the nuts with penetrating oil within &

without the door. Repeat several times over several days. Pray for the gods to

smile upon you

Get hold of a 5/16 UNF bolt at

least 4 & ideally 6 inches long & a slide hammer with some way of

attaching it to the bolt head. You also require a very high lift jack & tall

axle stands or a two post lift as you need to get the hole in the of the sills

at least 18inches/50cm in the air. Remove the sill covers, drilling out the

pop-rivets in the arches, pulling off the clips attaching the bottom edge to the

sillís flange & pulling the covers carefully off where they have been glued

along under the chrome trim. Screw

the bolt into the bottom of the hinge pin & hammer it out. Donít forget the

door is heavy & up in the air; you will need help to bring it down safely.

Donít use mole grips or pipe wrenches in the door as the burrs you raise on the

hinge pin will ensure you canít pull it out.

Removing the Door the Neo

Classical Method

If you canít get the pin

out you have to cut it in situ. I used a padsaw with replaceable hacksaw blades.

Open the door and tape a piece of sheet metal on the sill between the door and

sill at the hinge pin to protect the sill from the saw your going to cut the pin

with. Place a hydraulic jack under the door a raise slightly for clearance.

Using a fine metal blade cut the lower pin first then the upper. Donít forget

that the cutting stroke needs to be towards you & lubrication with a light

oil spray helps a lot. This is a laborious task so take breaks. An alligator saw

would do, but positioning it will be tricky. Remember you have to go through a

washer before you get to the hinge pin. Try & cut close to the sill/ wing as

preserving the head of the hollow bolt may help later. Get help to catch the

door so you donít drop it.

Assuming you now have a

door with a seized hinge pin on your bench and you are doing more than sorting

out the hinge you should next;

Strip the door down

Removing the windows isnít

too difficult as long as you know the following; The quarter light is held in by

two screws through brackets at the base of the window and a third rivet on the

front edge. The main window is held on by a single bracket on the front channel

and four rivets hidden beneath the glass channel on the rear & top sections.

There also a lot of black gunky stuff you may need to cut with a sharp knife

(being careful not to scratch the frame). The quarter light comes out first, you

have to press on the front end to clear it from the door surround & then

pull it away from the main frame. The window motor & lever comes out through

the ďloudspeaker holeĒ at the front of the door, but you have to flip it over so

the body of the motor comes out first. Be very careful not to drop the window.

To get the door handles off & the door lock (1Ē/26mm nut) you can look

through the tiny hole where the screw that holds the door trim on & see the

nuts illuminated by a ďstick lightĒ in the bottom of the door. This also makes

the door lighter.

Should you decide to strip

the door whilst itís on the car once you take off the outside handle make sure

you flip the door lock pawl closed so you donít lock yourself out.

Removing the Frozen Hinge

Pin

Theoretically you could

drill it out with a Ĺ inch drill, but you will almost certainly damage the

hollow bolt & have to remove that too. It is 21mm 9/16 inch diameter which

is too big a bit for a domestic drill. There is also the problem that household

drills run too fast & chatter about so it would be very difficult to do

& damaging the bobbin is likely. Grinding off the head of the hollow bolt is

feasible, but you would need to be skilled so as not to over heat the glass

fibre or even set it alight!

You will need a 1 1/8 inch

or 29mm spanner. The problem is there isnít enough room inside the door to get

half a flat of movement with the usual length of spanner of this jaw size. You

will have the same problem with

adjustables; short enough to move a flat means not enough leverage to get any

movement. You need both and ideally 2 combination spanners and an adjustable

with jaws at right-angles to itís handle. I also used a Dremel with a fibre

cutting disc & a big nut splitter.

Fig2 Custom Door Adjustment

Spanner

Alternatively buy a spare

1-1/8Ē box/open end (combination) wrench. Cut the end off at a desired length

say 5-1/2 inches / 14cm(fig2). Grind the working ends to the thickness of the

jamb nuts and cut the box end open as shown. These custom spanners are then very

helpful for reattaching the door.

Fig3 Access Hole

Cut an access hole for the

upper set of nuts by extending the existing one in the front edge of the door

(fig 3); this needs to be big enough to allow at least half a flat of spanner

movement (22 Ĺ degrees). First see

if youíre lucky & the nuts come loose following penetrating oil (on one side

of mine they did) you should be able to get them off with a combination of

spanners. Then cut the hinge rod, either using the Dremel or a hacksaw with the

blade inverted going from the hole in the front edge of the door to the

ďloudspeaker holeĒ. Donít cut the hinge pin before this because the alternative

& more violent method goes like this;

Look at the head of the

hollow bolt, can you get the bolt & pin to revolve in the bobbin ? You may

wish to use mole grips on the hinge pin to help, but if you donít need to do

this then you can cut a section out to make a gap to slip the nut splitter

through. Then use the Dremel to cut the deepest slit you can manage into both

nuts on the hollow bolt without damaging the bobbin. You could do a line of

drill holes as an alternative, but I believe this would require a second access

hole in the front of the door to get to the lower nuts. Otherwise you then twist

the hollow bolts round so that you can line up the nut splitter & use it to

spread the nuts before using the spanner again. Stabilise the nut splitter with

an adjustable to avoid pressure on the bobbins. Be very careful that you are

always able to hold the hollow bolt somehow to allow the nuts to move either

using a mole grip on the frozen hinge pin or a spanner on the head. If you end

up with a rotating hollow bolt & nothing to grip I would suggest carefully

drilling around whatever remains of the bolt head to destroy the head &

washer so it falls into the door.

Approaches that donít

work

Impetuosity. Nut splitters

alone arenít strong enough & youíll tear the bobbins out. Heat will set the

door on fire. There isnít enough room for a standard angle grinder & the

large diameter of the cutting disc makes it impossible not to damage the bobbin

& potentially a lot of other things including you.

This task will take a

couple of hours if it all goes well, a couple of months on & off if it

doesnít. But love of old sports cars is like an affair with an older women. When

theyíre young all you need to do is throw money at them, as they mature they

require more thought effort & attention.